When ‘Cheaper’ Costs You More: Mild vs Stainless Steel

Linea Seat and Bench (1800mm) with aluminium Curly Birch battens, Pale Eucalypt Green frame.

Results of a corrosion test exposing powder coated mild steel to salt water.

While mild steel may seem budget-friendly at first glance, its tendency to corrode, chip and degrade under real-world conditions leads to higher lifecycle costs – financial and environmental.

That’s why Street Furniture Australia has transitioned all powder coated frames from mild steel to stainless steel over the past eight years.

The switch delivers more than just better corrosion resistance – it’s about ensuring a refined finish, clean design lines, reduced maintenance and delivering sustainable products that endure for decades.

Public Realm Performance

Stainless steel offers excellent resistance to corrosion and rust.

Grade 316, often called marine-grade, is particularly suited for coastal environments (within 10km of the ocean). Its chemical composition resists pitting and crevice corrosion, caused by salt and even urban pollution.

Mild steel is galvanised, coated or painted to prevent rust. However, as it is softer and more ductile, it is prone to chipping. Even a small chip causes the exposed steel to rust quickly, leading to blistering, flaking and peeling.

Stainless steel resists corrosion even when the coating is breached, due to a protective oxide layer.

Why are corrosion and rust so bad?

Rust is sharp, brittle, flaky and can cause total material failure over time, including weak joints, bent or broken frames, and collapsed parts under weight. Rust can be a public health and safety hazard, and liability risk for the custodian.

Additionally, neglected products contribute to poor public perception of a space, which may lead to increased vandalism and antisocial behaviour.

Over the product lifecycle, increased maintenance and part or total replacements cost more than using higher-grade materials like stainless steel up front. See life-cycle costing comparison by ASSDA.

Environmental Impact

Over the total product lifecycle, stainless steel delivers a lower lifetime environmental cost than mild steel due to low maintenance needs, longer lifespan (can last decades) and infinite recycling potential.

Mild steel requires frequent recoating to seal it from air and moisture, and shield it from corrosion – which increases chemical and fuel use by maintenance crews – all adding to the environmental impact. In recycling, it often loses performance or ends up in lower-grade products.

All Street Furniture Australia products are additionally certified carbon neutral by Climate Active.

Minimalist Precision

Stainless steel enables more minimalist, refined street furniture designs compared to mild steel and fabricated aluminium due to a combination of strength, durability and surface finish.

The Linea range showcases the superior finish and precision possible with stainless steel. Linea seating, tables, bollards and bicycle parking are constructed from 6-8mm thick stainless steel frames. This allows for a strong, streamlined frame. Fabricators can also achieve clean welds, which can be polished smooth.

Linea Seat, stainless steel frame.

The finish of mild steel is coarser than stainless, with bulkier welds. And aluminium alternatives, while lighter, require thicker sections and reinforcements, and lack the same level of refinement.

Product not by Street Furniture Australia. Not suitable for minimalist forms: aluminium frame requires bulk and additional gussets for reinforcement.

Street Furniture Australia began transitioning from mild steel to stainless steel with the Classic Plaza frame. The lift in finish quality is apparent.

Top: Mild Steel, galvanised and powder coated.

Bottom: Stainless Steel, sandblasted and powder coated.

Classic Plaza Seat in situ at the Australian War Memorial in Canberra ACT.

Pre-treatment is Key to Make Powder Coating Last

In addition to replacing all mild steel frames with stainless steel, Street Furniture Australia implements a high-grade sandblasting process on stainless steel surfaces to achieve optimal surface profile prior to powder coating. This significantly improves mechanical adhesion and resistance to chipping, contributing to long-term aesthetic and structural integrity.

Aluminium components are subjected to a comprehensive multi-stage pretreatment – typically including degreasing, deoxidising, and chromate or zirconium conversion coating – prior to in-house powder coating application, ensuring maximum corrosion resistance and coating durability.

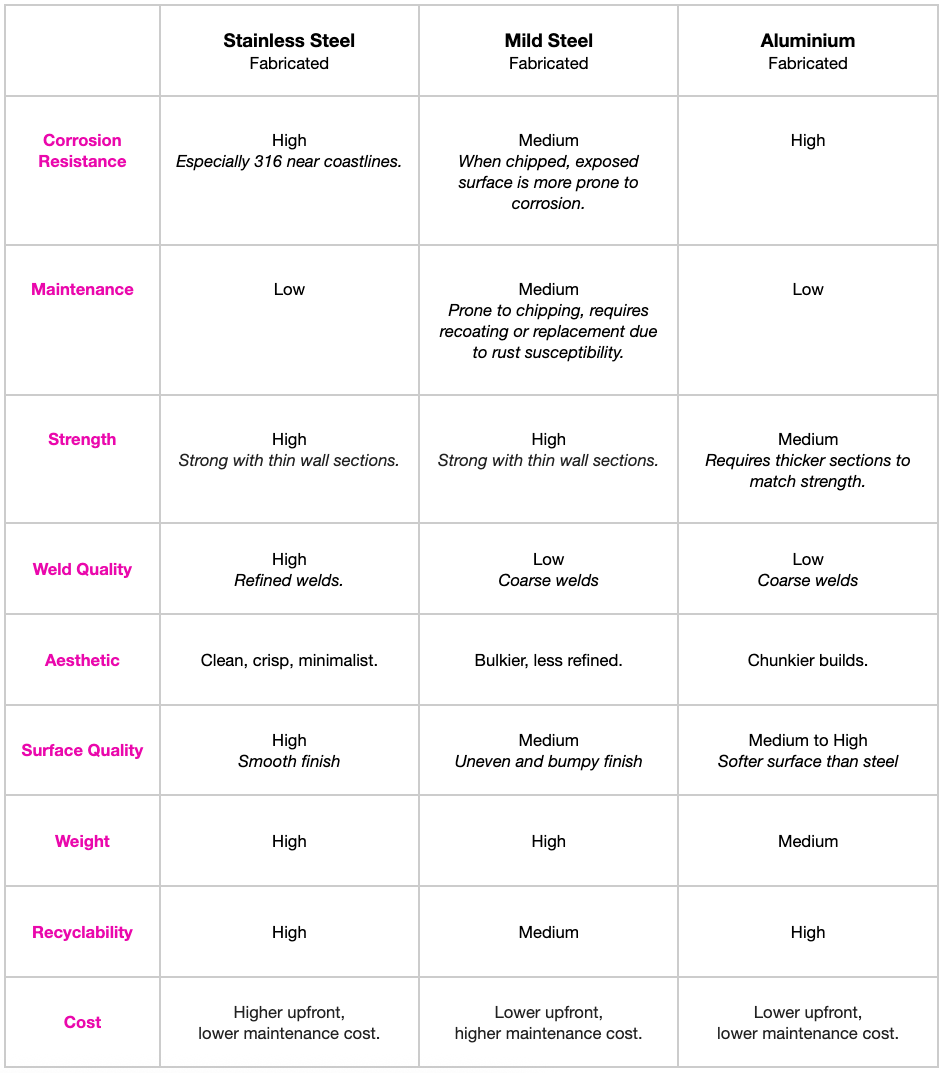

Material Comparison: Powder Coated Frames

If you would like to learn more, please book a presentation, or visit our factory. Factory Tours and Studio Presentations run regularly for specifiers, councils and other built environment professionals.